Glamour Collection

I am delighted to present my new Glamor Collection idea for refining metal surfaces.

Mrs. Löw, how did this idea of refining metal surfaces come about?

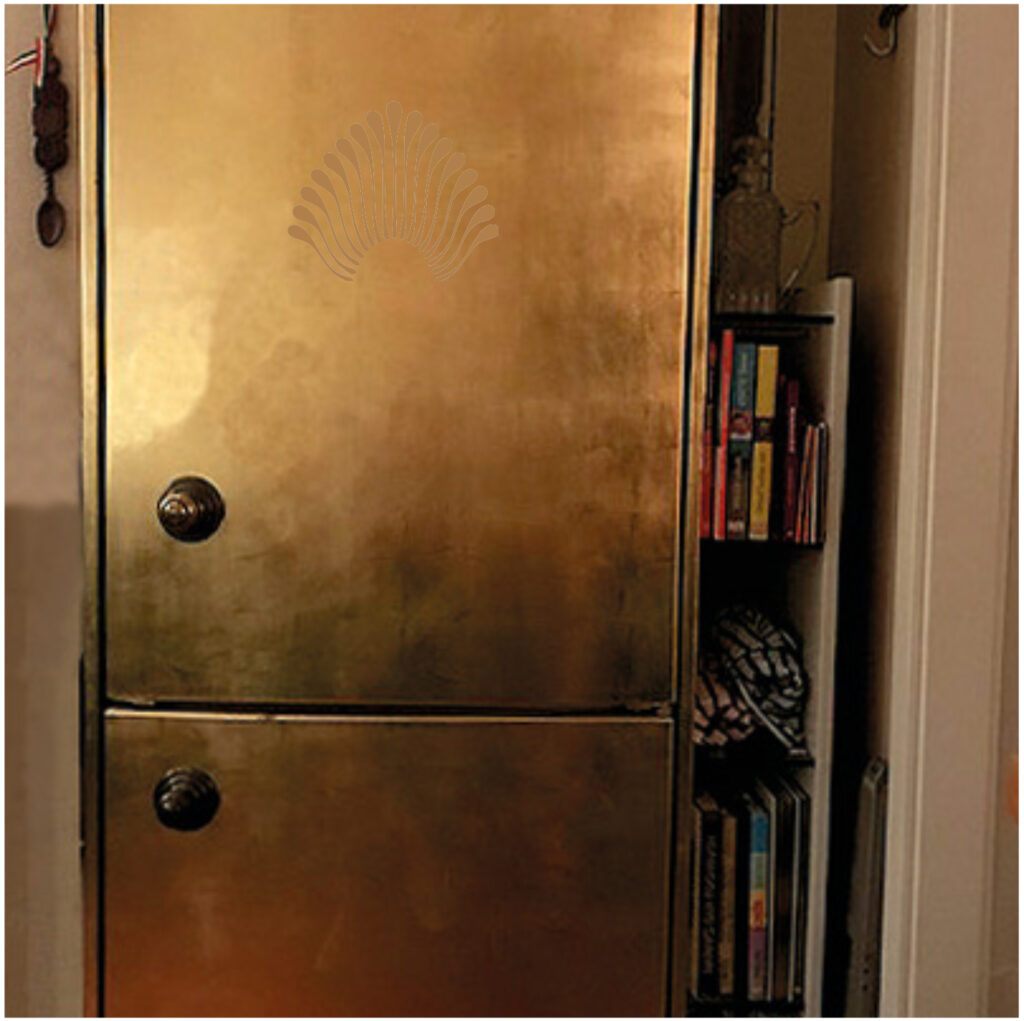

It all started with an idea I had for the exterior of a refrigerator. I wanted to redesign the functional character of a stainless steel or flat metal surface: make it nobler, different and more innovative.

The surface has a unique aura!

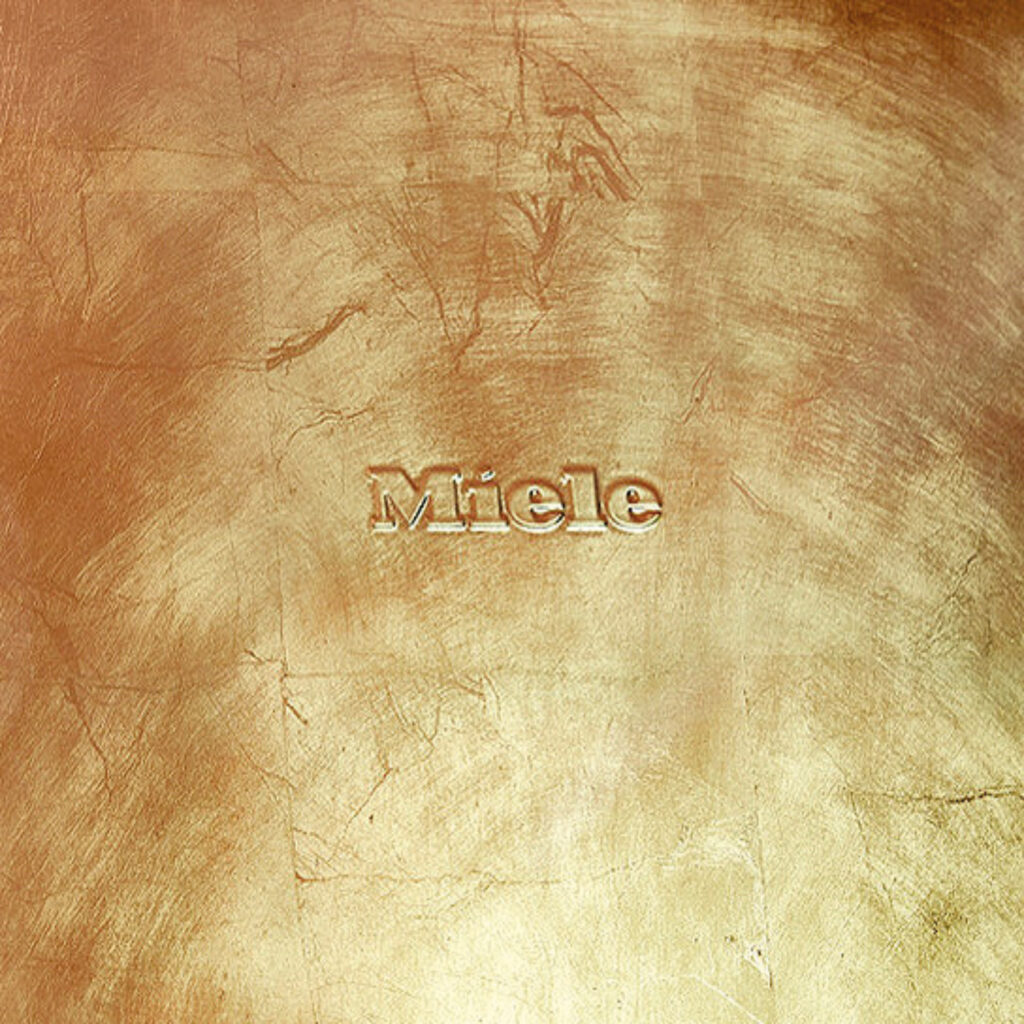

It’s beautiful, aesthetic and exciting. It’s for objects or surfaces that are in view, such as a refrigerator, something you see when looking into an open-plan kitchen. The use of leaf metals and precious metal leaf automatically leads to a dynamic surface design. This is influenced by the different sizes of the leaf metal. The fine folds which involuntarily form a structure also contribute to this.

What challenges did you face?

The first challenge is to create the bond between the leaf metal and the metal surface. The second challenge is to maintain overall surface durability. We are all familiar with leaf metals applied to wooden picture frames. In this context, surface durability is not necessarily a consideration. A picture frame or a mirror is not being constantly touched and manually stressed. Wipe or scratch resistance is not required in this case. With various work processes, we have achieved a very fine, thin surface finish by means of applying coats of automotive paint. The resulting visual effect is reminiscent of Japanese lacquers.

Have you applied for a patent for this process?

Yes, we have filed a patent for this formula. This work is hand-crafted and can be applied to any metal and stainless steel construction. So it doesn’t have to be a fridge. Curved or other surfaces can also be finished with it.

A custom-made structure created by a metal worker for a kitchen island or a front as well as other interior design elements can be refined with this process. Handmade and priced according to the surface area required, numerous areas of application are possible.

Which metals can be used for this and where?

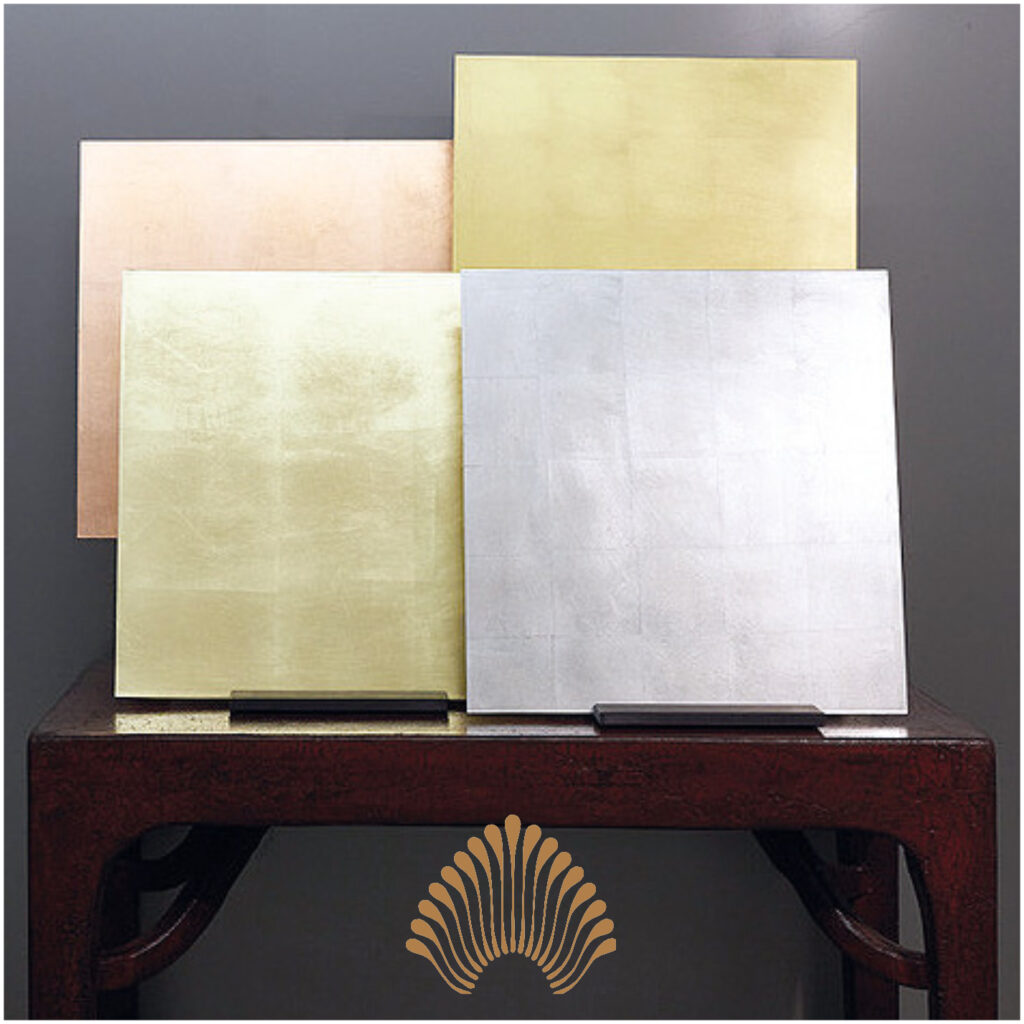

Copper, brass, aluminium, silver, white gold, yellow gold, rose gold, palladium, platinum, platinoro. I can imagine a very wide range of applications:

Yacht building, creating kitchens, refining vertical surfaces for various interior requirements; also fireplaces and chimneys or modern radiators, for example. Sustainability plays a strong part in my work here when modifying and refining existing pieces of furniture. I also have in mind high-end restaurants and hotels, powder rooms, design highlights in restrooms; bar equipment and carefully lit back walls.

Applied to surfaces, I see its use more for vertical refinement, where light striking it particularly emphasises this unique structure. When used purposefully, it can have a very exciting effect, especially in combination with contrasting materials. We can also deploy it to refine small pieces of furniture, as well as for smaller horizontal surfaces, curved surfaces and edges.

How do you look after this product?

Although this is a unique product, it only requires minimal care: it is best cleaned with a damp cloth and then wiped dry.

How much does it cost?

This surface refinement can be applied to any custom-made metal or stainless steel surface. The price is always based on the total area. However, the nature of the design and construction of the object in question is also taken into account for the final price calculation.

As this product is tailor-made, an individual quotation is calculated for each project.